Building the Pro XD

Polaris Commercial utilizes the manufacturing and engineering capabilities of Polaris Inc. to deliver our Pro XD vehicles with the unmatched safety features, unrivaled durability, and enhanced serviceability our commercial customers expect and deserve.

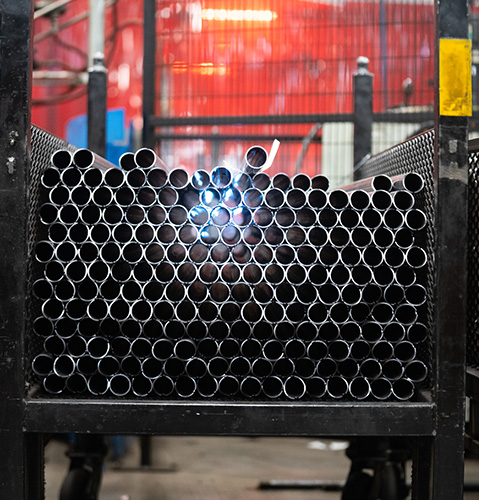

OUR MANUFACTURING PLANTS

Where hard work, raw materials, and dedication come together to bring the Pro XD to life.

OUR PROCESS

From receiving raw materials to assembling the final nuts and bolts, Polaris Commercial vehicles are Built to Work for the task at-hand.

LE PRODUIT FINAL

Polaris sets the bar high when it comes to manufacturing the Pro XD.

QUALITY INSPECTIONS

From initial research and development, all the way to final assembly, our manufacturing processees include mutiple quality checkpoints and inspections.

AUTOMATION

Our skilled workers utilize automated innovations throughout the build of each Pro XD including robotic weld cells, DC torque tools, and Automatically Guided Carts (AGCs).

FACTORY-INSTALLED ACCESSORIES

A variety of our accessories are factory-installed including: roofs, windshields, rear panels, doors, rearview mirrors, filter gauge, speed limiting and electric bed lift. You can also order EPS and heater kits if they are not included in the base model.